|

Press

the "Forward" button to continue.

Testing |

Splice Protection and Testing |

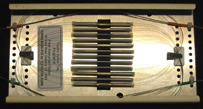

Whether fusion or mechanical, once

the splice is assembled, it must be protected

from moisture and movement within an enclosure. |

|

Whether fusion or mechanical, splices

should be tested with a loss meter or OTDR for quality.

After testing, the splice should be mounted in a

proper splice holder or tray. The splice holder

should be firmly secured within a enclosure.

Splices

must be protected against vibrations. Mechanical

splices may work loose or become high loss after

excessive vibration.

|

| Fibers

must have all outer jacket and strength member materials

removed before splicing. 900 micron or 250 micron

buffered fiber strands are quite delicate, and excessive

bending of these fibers can result in high loss.

Often these bends occur within the splice enclosure.

Once completed, splices should be tested, and carefully

placed into their holders, without excessive bending

of the fiber strands. |

|

|

| LESSON

REVIEW |

Key

Points:

1.

Once completed, all splices should be tested.

2. Splices require protection from environment and vibration.

|

Pop

Quiz:

True or False

Fusion splices do not require testing.

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|