|

Press

the "Forward" button to continue.

Field

Experience and Tips |

Visible Light and Laser Testing |

Fiber

link “continuity” means that the glass fiber is

continuous, I.e. not broken underneath the jacket.

A flashlight is a very handy tool for fiber link

testing. By shining a regular flashlight into

a fiber connector, the continuity of the fiber

can be quickly determined. If the light is visible

at the other end, the fiber is not broken, and

should be useable for signal transmission. If

the light isn’t visible, the fiber is broken mid-span

in the link, or most likely there is a bad connector

with the fiber broken within the connector body. |

|

|

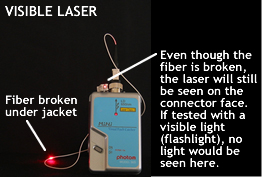

Visible

lasers provide some indication of the quality of

fibers, and can be used to find breaks in a fiber

cable under certain circumstances. A visible laser

can indicate a bad connector-if the plastic ferrule

emits the laser light from the sides, the fiber

is broken within. Visible lasers can also show where

a fiber is bent excessively, provided that the jacket

material on the fiber is of a light color. |

ROLL

CHECK

When undertaking an expensive installation, such

as a direct burial fiber, it is important to test

the fiber strands under the jacket BEFORE the cable

is placed into the ground. Bare fiber ends, without

connectors, must be “cleaved”, using a special tool

to break off the fiber end at a 90% angle. Uncleaved

fibers will have an irregular end, and light energy

cannot be injected into the core. The roll of fiber

will have both ends available, with one in the center

of the roll and one on the outside. When the light

is injected into the cleaved fiber strand end, it

will be visible at the other end if the fiber hasn’t

been broken in manufacturing or shipment. The technician

may have to strip both ends of the fiber so that

the light is made visible. |

|

INSTALLATION

CHECK

Once the fiber has been installed, it is a simple

matter to shine the light into the cleaved fiber

end again, to verify that the fiber strands were

not broken during the installation process. |

Once

the connectors have been installed, a visible light

injected into one connector should be visible at

the other end. This indicates that the connectors

pass light, and are probably functional. Connectors

may pass visible light even if they are of poor

quality, so completed fiber links should be tested

with an optical loss meter set. If a fiber link

passed visible light before the connectors were

installed, but light doesn't pass after the connectors

were put on, one or both of the connectors is defective.

The laser light can be used in most circumstances

to find a bad connector. Connect the laser to the

connector in question, and bend the fiber immediately

past the connector boot. If the laser light shines

through, the light is passing through the connector

itself. If the laser isn’t glowing, the connector

is bad and needs replacement. Once

the connectors have been installed, a visible light

injected into one connector should be visible at

the other end. This indicates that the connectors

pass light, and are probably functional. Connectors

may pass visible light even if they are of poor

quality, so completed fiber links should be tested

with an optical loss meter set. If a fiber link

passed visible light before the connectors were

installed, but light doesn't pass after the connectors

were put on, one or both of the connectors is defective.

The laser light can be used in most circumstances

to find a bad connector. Connect the laser to the

connector in question, and bend the fiber immediately

past the connector boot. If the laser light shines

through, the light is passing through the connector

itself. If the laser isn’t glowing, the connector

is bad and needs replacement. |

|

|

| LESSON

REVIEW |

Key

Points:

1.

A flashlight or visible laser can be used as an inexpensive

tester for fiber optic links.

2. A common flashlight can be visible up to three miles in

a multimode fiber link.

3. Common visible light tests include pre-testing fiber rolls

before installation, checking fiber strands for breakage after

pulling, and checking connectors.

4. Fibers without connectors installed will need to be "cleaved"

to a 90 degree angle before a visible light will enter.

|

Pop

Quiz:

True or False

A flashlight can be used to show a break in a fiber cable.

|

Key

Terms:

1.

Visible light

2.

Laser tester |

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|